After decades of neglect, Mallorca’s traditional handcrafted hydraulic tiles are making a comeback. And it’s not hard to see why. Made one by one using a hydraulic press, they can withstand a century of wear and tear and provide a rich tapestry of lustrous color to homes throughout the island.

For the Huguet family, the 1960s Mallorcan development boom meant bust. Just as things started looking up, people stopped looking down – substituting the rich tapestry of hydraulic floor tiles found in most homes with cheap quarry tiles or covering them with carpet. The hundreds of hotels spawned by the rapid growth in tourism had no interest in handcrafted tiles, made one by one in a laborious process of pouring pigmented cement and marble into molds. By the end of the decade, all 80 hydraulic tile workshops on the island had closed.

“Every village had two or three factories,” says Gabriel Huguet Ballester, who in 1996 reopened the family business in the town of Campos. Founded in 1933 it had gone the way of other traditional industries as labor costs – and the appetite for cheap materials –grew. “As Mallorcans became more prosperous, they turned their backs on the past,” he explains. “But then in the late 1980s and early 1990s, they started appreciating their heritage again. And remember, many foreigners also value traditional materials.”

And not merely on aesthetic grounds. With hydraulic tiles, the colors are not painted on, but are cast in a mold using a mixture of colored cement and powdered marble. So instead of a thin, vulnerable veneer of paint or a print-on design, the colors run between 3-6mm deep. This makes the colored surface extremely hard-wearing and enduring.

It’s a time-consuming process, though, as a trip to the factory will show.

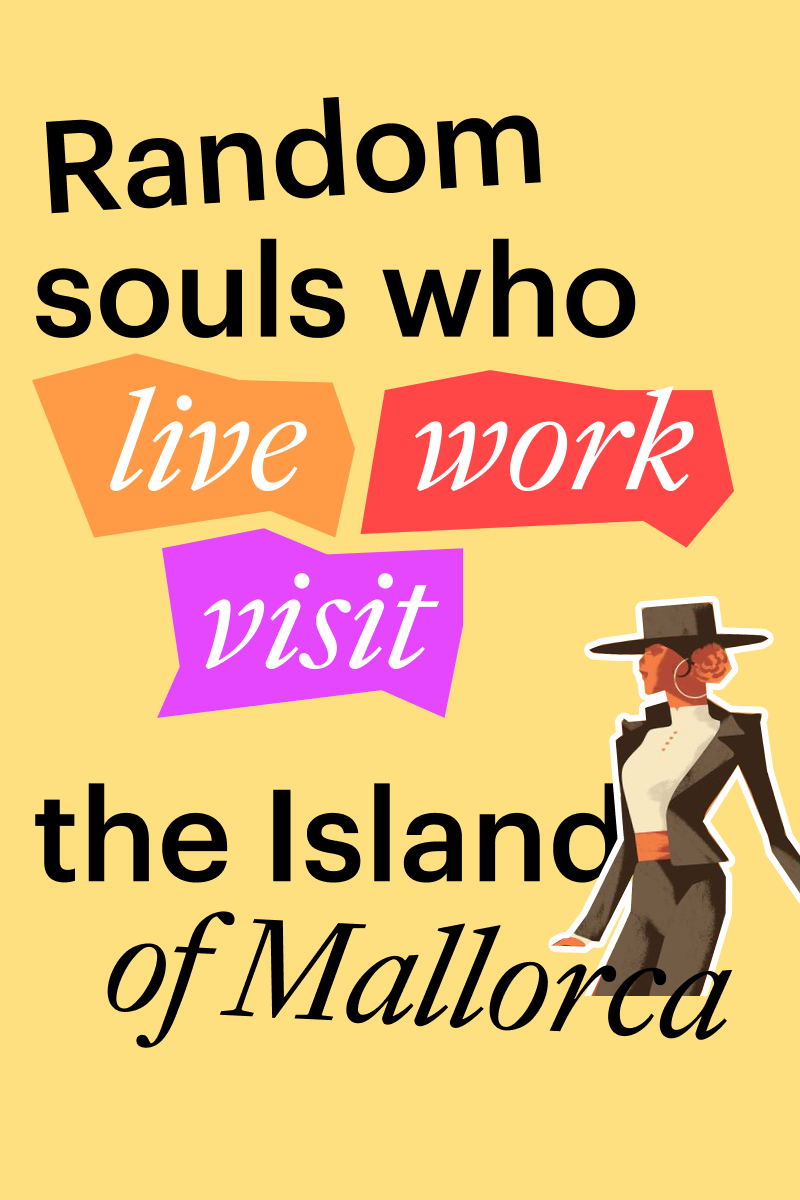

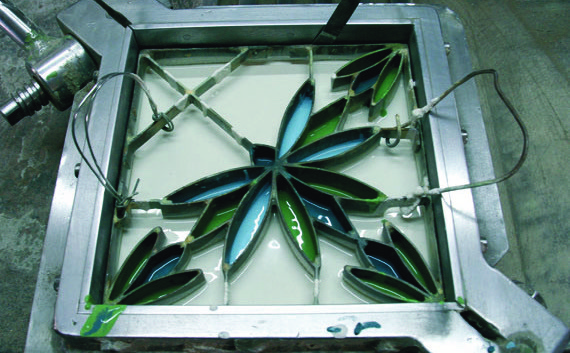

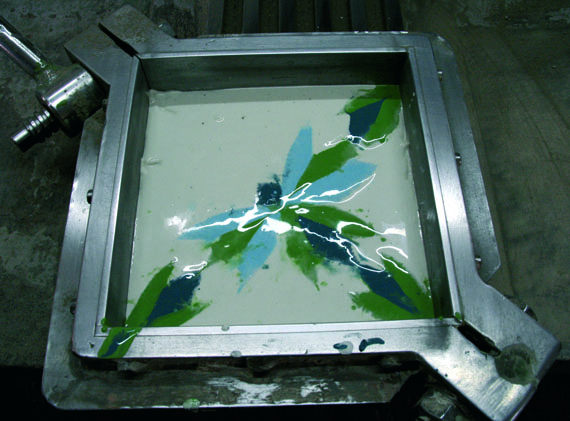

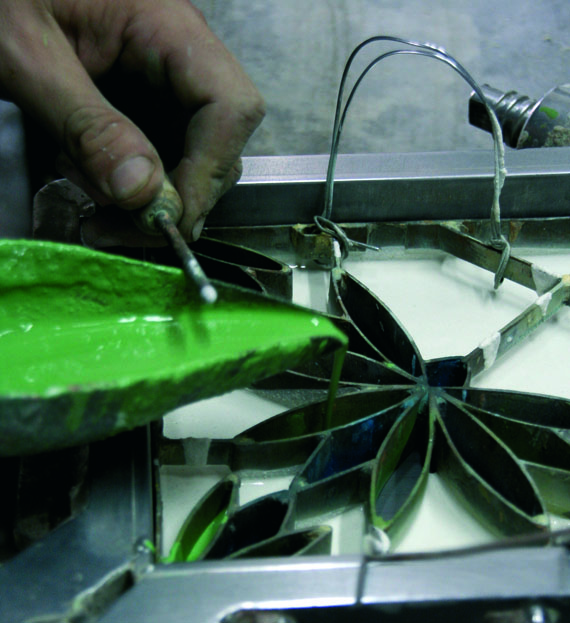

First, the individual tile mold is meticulously cleaned. Then the appropriate pattern stencil – usually made up of cells in geometric or floral designs – is placed in the mold. The colors are then prepared – a dense mix, generally of two-thirds pigmented cement with one-third powdered marble, which lends the tiles their trademark lustrous colors.

No chemicals or resins are added, and the appropriate colors are hand-poured into each cell of the stencil. Once all the compartments have been filled with the colored mix, the stencil is delicately removed. To prevent colors from running they are immediately dusted with dry cement powder. The wet tile, still in its mold, is then placed in a hydraulic press and briefly compressed under 100 kilos of pressure.

The tile is carefully finished by hand, after which it will be placed in a water bath for several days.

“We’ll take orders for anything from one tile up to 1,000m2,” explains Gabriel. “A lot of customers come with their own designs too.”

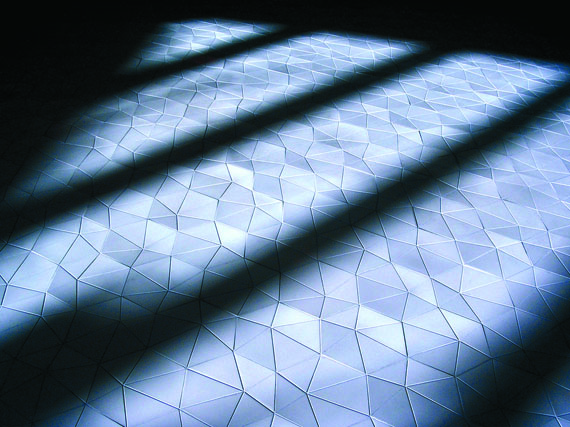

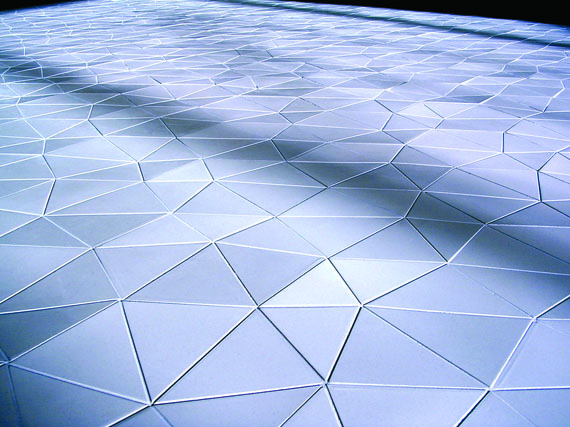

Like Sybilla, one of Spain’s most popular designers, who approached the company with her own motifs. Or Swiss architects Herzog & de Meuron, for whom Huguet produced a startlingly modern collection for the sci-fi Fòrum de les Cultures building in Barcelona, where the “depressed hexagonal tiles create exquisite undulating ceramic ‘carpets’ in the lower foyer”. So says the Architectural Review.

“Though we started out making traditional tiles, little by little, we realized we could use the same techniques to do contemporary things,” explains Gabriel.

With their engaging mix of traditional and modern he and his fellow workers at Huguet certainly look set to weather any future boom or bust.

Huguet, factory and showroom: Camí de Ciutat Vell, Campos. Tel: 971 650 609 www.huguetmallorca.com.